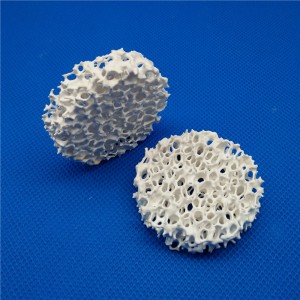

Sesefa sa Alumina Ceramic Foam bakeng sa ho sefa ha Aluminium Alloy Molten

Sesefa sa Alumina Ceramic Foam bakeng sa ho sefa ha Aluminium Alloy Molten

| Boholo (mm) | Boholo (inch) | Sekhahla sa ho tšela (kg/s) | Bokhoni ba ho sefa (ton) |

| 178*178*50 | 7*7*2 | 0.2-0.6 | 5 |

| 228*228*50 | 9*9*2 | 0.3-1.0 | 10 |

| 305*305*50 | 12*12*2 | 0.8-2,5 | 15 |

| 381*381*50 | 15*15*2 | 2.2-4.5 | 25 |

| 430*430*50 | 17*17*2 | 3.0-5.5 | 35 |

| 508*508*50 | 20*20*2 | 4.0-6.5 | 45 |

| 585*585*50 | 23*23*2 | 5.0-8.6 | 60 |

| Lintho tse bonahalang | Alumina |

| Mmala | Bosoeu |

| Pore Density | 8-60ppi |

| Porosity | 80-90% |

| Refractoriness | ≤1200ºC |

| Matla a Kobehang | >0.6Mpa |

| Matla a Khatello | >0.8Mpa |

| Boima ba molumo | 0.3-0.45g/cm3 |

| Ho hanyetsa mocheso oa mocheso | 6 linako / 1100ºC |

| Kopo | Aluminium, Aluminium alloys le tse ling tse Non-ferrous alloys |

1. Hlakola mokelikeli oa tšepe o qhibilihang

2. Sistimi e nolofalitsoeng ea ho kengoa

3. Ntlafatsa sebopeho sa metallurgic ea li-castings

4. Fokotsa ho se tsotelle ha li-castings

5. Ntlafatsa sekhahla sa boleng ba ho lahla

6. Fokotsa ho lahlela bofokoli ba ka hare ho oxidation

7. Fokotsa mefokolo ea holim'a metsi ka mor'a ho etsa mechine ea li-castings

1.Mokelikeli o eketsehileng

Ho tlosoa ha li-inclusions ho etsa hore tšepe e be metsi a mangata, e leng se etsang hore ho be bonolo ho tlatsoa ha hlobo, sebopeho se betere sa ho lahlela, le karolo e ntle e tšesaane ea castability.

2.Reduced Mold and Die Wear

Ho tlosoa ha li-inclusions le lithōle tse ling tse sa tsitsang ho tloha ho qhibiliha ho fokotsa li-die soldering le tšebelisano ea hlobo ea tšepe, e senyang bokaholimo ba hlobo le bophelo ba tšebeletso.

3.Longer Tool Life

Oxide hammoho le li-intermetallic inclusions li etsa "libaka tse thata" tse senyang lisebelisoa ho machining le ho qeta mesebetsi.Filtration e fokotsa ho roala ha lisebelisoa le ho eketsa tlhahiso.

4.Ho hana ho fokolang

Inclusions nucleate porosity, e baka meokho e chesang nakong ea ho tiisa, e baka bofokoli bo ka holimo bo senyang ponahalo, 'me hangata e fokotsa thepa ea mochini.Maemong a mangata, likhahla tsa filtration li hana ho tloha ho lisosa tse joalo ho ea ho zero.Ho ntlafala ha lihlahisoa ho ea ho 100% le ho fokotsa litekanyetso tsa ho lahloa ho isa ho kapa haufi le 0% li tloaelehile.

1. Ho lahla lehlabathe

2. Ho lahla likhetla

3. Lefu la khatello e tlase

4. Ho lahla hlobo e sa feleng

5. Litsamaiso tsa ho tšoara le ho fetisa